- Home

- |

- About Us

- |

- Capabilities

- |

- Quality

- |

- Contact us

- |

- Quote

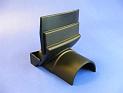

Plastics

Plastic injection molding was one of the first processes in operation at Mercury EPM. We currently produce over 1000 unique molded parts on 22 molding presses. We stock over 40 engineering-grade resins which we blend with colorants and additives as needed to meet customer specifications.

Many of our molded products include metal inserts or decorative in-mold appliqués. Our molding presses are machine controlled to maintain proper process parameters and ensure conformance to product specifications. A computer-based scheduling and tracking system is used to optimize resource utilization.

Some molded products are shipped directly to our customers “as molded,” while others undergo finishing operations. Still other molded components are integrated into electronic or coil-wound products.

Our plastics finishing operation features a CNC lathe and CNC milling machine. Other secondary processes include tumble blasting, drilling/tapping, pad printing, assembly, testing and retail packaging and kitting.

- © Mercury Marine

- Terms & Conditions

- Privacy Policy

- Mercury is a division of Brunswick Corporation